Our range of eco-friendly and energy-efficient Prium® melting technologies ensures that we have the right solution for every application, whatever the glass type, quality, fuel or end use. Each line is designed for maximum longevity, optimum efficiency and with the environment in mind.

ELECTRIC

A green alternative

Prium® E-Melt and Prium® E-Boost

Design your energy-efficient melting process with e-boosting for lower emissions and increased output.

Oxy-fuel

Greater EFFICIENCY

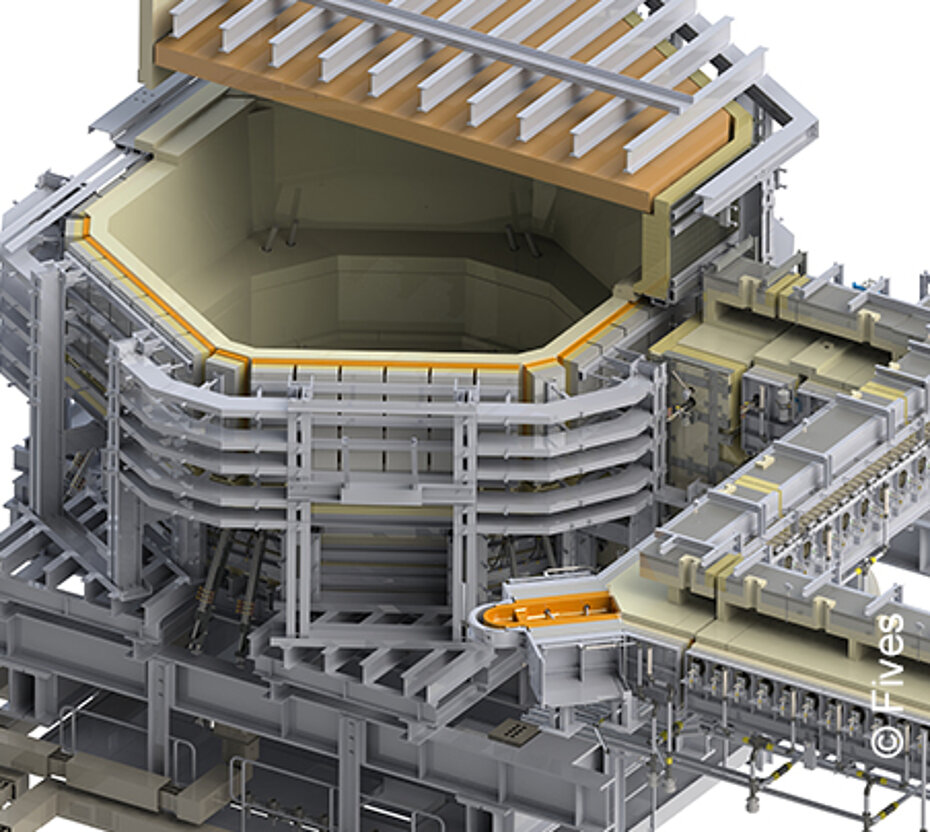

PRIUM® OXY-MELT and H.R.A.TM technology

Reduce flue gas temperatures, maximize glass quality and save energy with oxy-fuel combustion.

Float glass

Low on energy, high on quality

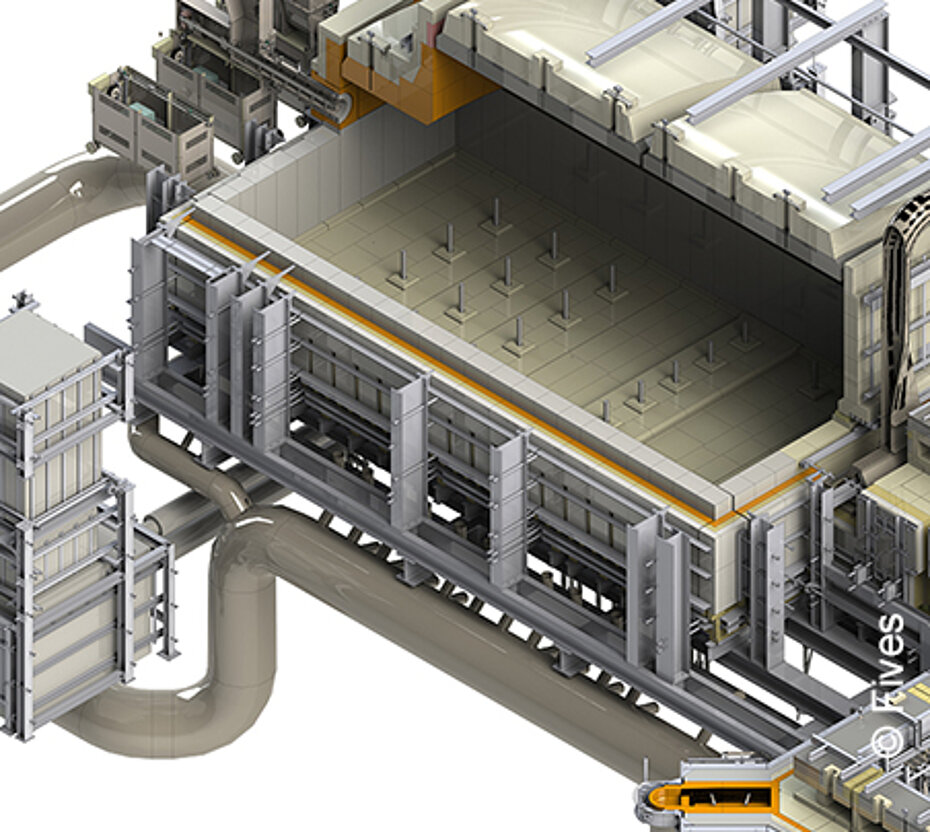

Prium® Float-Melt and L.E.M.® technology

Produce high quality automotive, solar and architectural glass.

Hybrid

FLEXIBILITY & GREEN ENERGY

PRIUM® ECO-FLEX AND H.R.A.™ technology

Achieve dramatic reduction of emissions in container glass production.